SMARTFLEX COMPACT PLUS

This modular material-handling system brings unlimited growth potential to shop floors of all sizes.

The SmartFlex COMPACT series provides flexible, expandable automation into a compact footprint.

With an installation footprint of less than 32’x42’ (3015), the SmartFlex COMPACT is a purpose-built load/unload unit for maximum productivity in minimum space.

This space-saving design comes in a number of configurations, making automation possible. Plus, today’s software capabilities and cycle times make even short-run job shop environments good candidates for automation.

BUILD YOUR PERFECT PRODUCTION LINE

- Our laser automation line is fully modular, giving you and your shop the perfect opportunity to create a machining and fabrication solution that’s custom-built to your exact specifications. And with configurations that require up to 30% less floorspace than other setups, designing the setup that’s right for you has never been easier or more cost-effective.

PRODUCTIVITY THAT’S GOOD TO GROW

- From small fabrication shops to massive lights-out operations, our laser automation line comes ready with a wide range of options that make it a great fit in nearly any scenario. This isn’t something you’ll need to replace in 5 years.

EXPERT INSIGHTS INCLUDED

- Not sure where to get started? Not to worry. Our laser automation experts will work with you to determine the right combination of machines, storage towers, product carts, and break-in stations. Together, we’ll help you create an adaptable, future-forward solution you can rely on to meet the needs of today and the challenges of tomorrow.

Available in both 3015 and 4020, the The SmartFlex COMPACT Plus automation system is a robust, modular productivity platform that can be easily altered and augmented—all at your command.

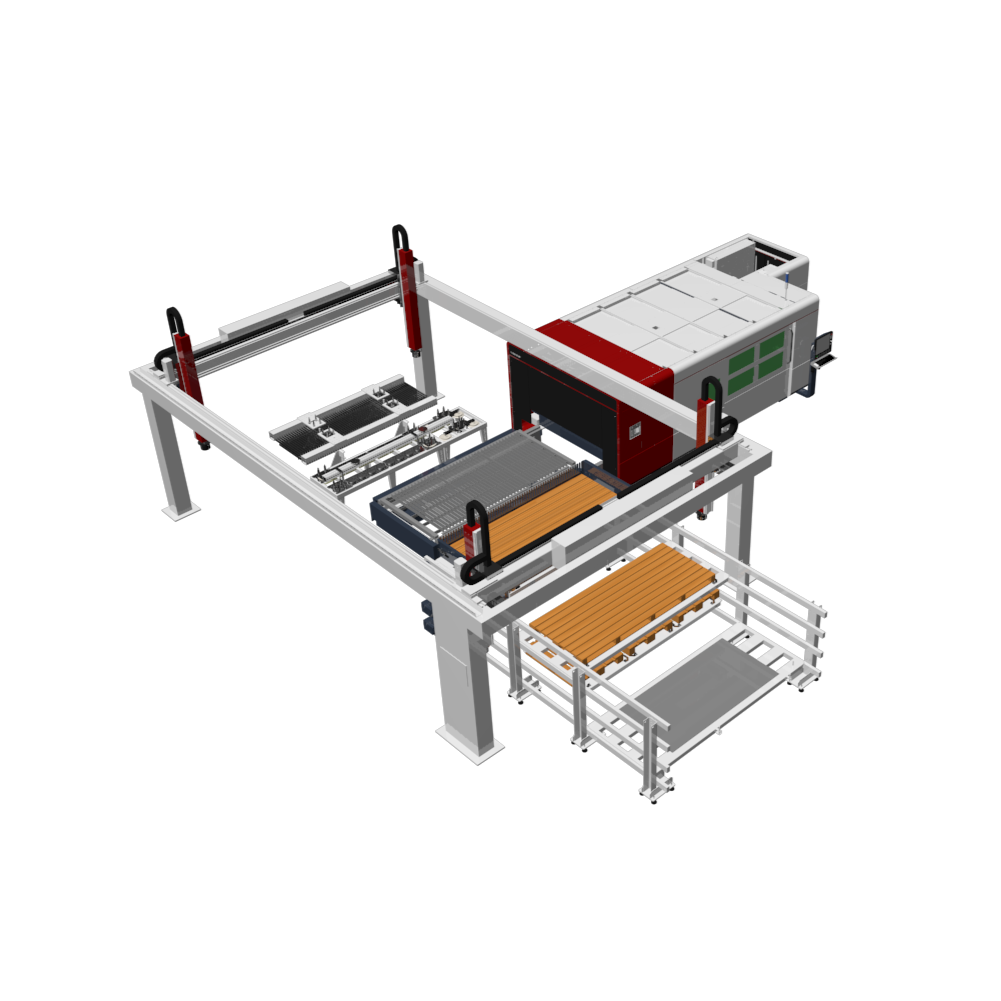

SmartFlex COMPACT Plus Base

Our most compact system was aptly named. With a footprint of less than 32’ X 42’ (3015) or 40' x 43' (4020), this full featured and expandable system anchors our COMPACT line of automation. With a load time of 75 Seconds regardless of material thickness, this powerful and reliable system will grow with you.

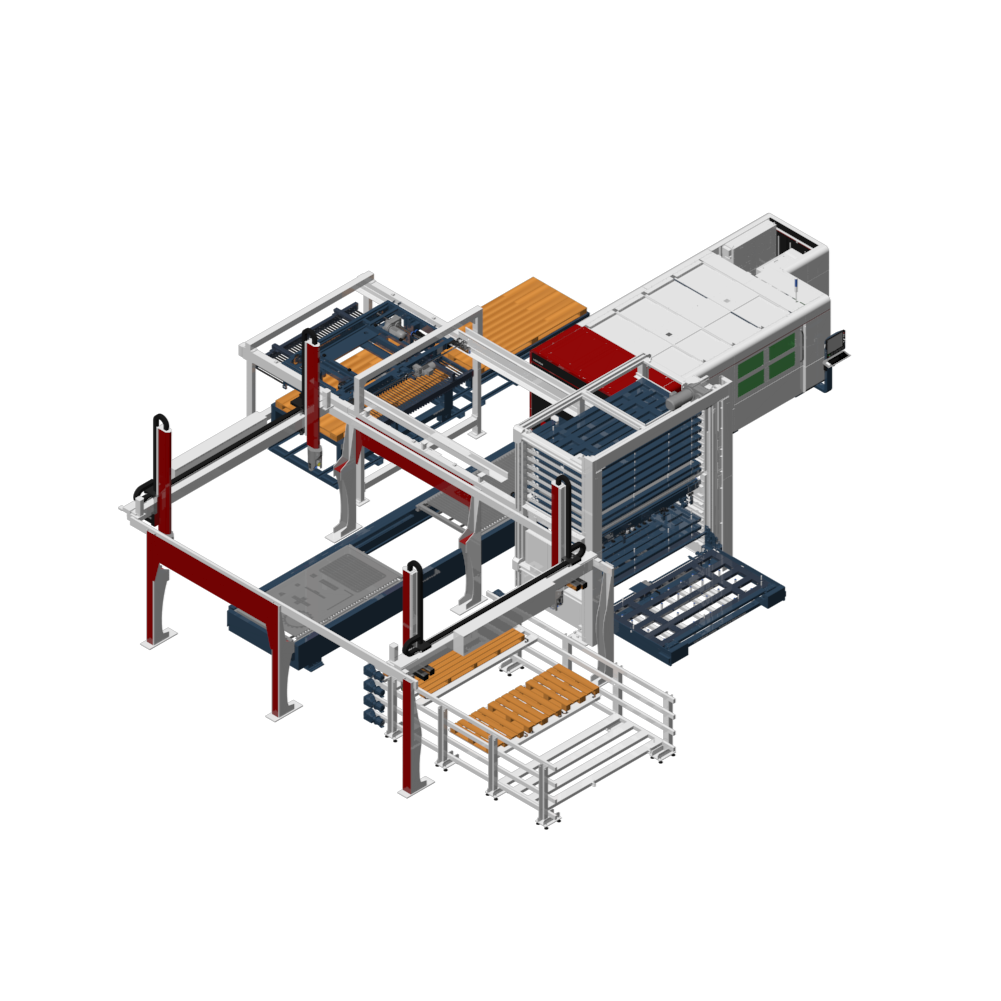

SmartFlex COMPACT Plus Warehouse

All of the benefits of our COMPACT system with dramatically enhanced storage ability. From 6 to 34 (3015) or 6 to 30 (4020) shelves of storage, the COMPACT Warehouse can store both raw material and finished goods for many hours of lights-out production.

CAPABILITIES:

- With an installation footprint of less than 32’x36’ (3015), the SmartFlex COMPACT PLUS is a purpose-built load/unload unit for maximum productivity in minimum space

- Completely modular and expandable

- Full load/unload cycle in approximately 75 seconds (3015)

- Multiple combinations of material pallets and product pallets

- Material pallets can be set up to work with 6-34 shelves

- Two loading locations available for quicker material changes in a two-machine production cell

- Finished goods pallets are always located below raw material to make sure falling slugs don’t interrupt operation

COMPONENTS:

- Vacuum-load system with thickness detection, sheet separator, and Aerial Positioning

- Heavy-duty clamshell fork unload and system with built-in sheet-raking system

- Heavy-duty, full-size sheet load/unload capacity (up to 1”)

SYSTEM INFORMATION:

- Fully compatible with DiamondFAB laser automation software

| Compact Plus System Specification | ||

| MODEL | 3015 | 4020 |

| Cycle Time: Seconds | 75 | 85 |

| Load Weight: lbs. /shelf | 6,600 | 6,600 |

| Unload Weight: lbs. /shelf | 6,600 | 6,600 |

| System Footprint (Base): L x W ft. | 32’ x 42’ | 40’ x 43’ |

| Shelf Count: | 2 (1 Load and 1 Unload) | 2 (1 Load and 1 Unload) |

| Compact Warehouse Plus System Specification | ||

| MODEL | 3015 | 4020 |

| Cycle Time: Seconds | 75 | 85 |

| Load Weight: lbs. /shelf | 6,600 | 6,600 |

| Unload Weight: lbs. /shelf | 6,600 | 6,600 |

| System Footprint (Warehouse): L x W ft. | 37’ x 42’ | 43’ x 51’ |

| Shelf Count: Min to Max | 6 to 34 with dual tower | 6 to 30 with dual tower |

RELATED SOLUTIONS

-

EDM AUTOMATION

The ultimate solution to improve throughput, increase production, reduce manpower, and be more competitive.

learn more -

LASER AUTOMATION

Leave your bottom line beaming.

learn more -

PRESS BRAKE AUTOMATION

Stretch your throughput capacity to new levels.

learn more -

MILLING AUTOMATION

Increase throughput and maximize your resources.

learn more

-

"Ever since we’ve had the (SmartFlex Element Type R) automation tower, it has been an absolute game changer. I think that if you don’t have an automation system on your laser, you are wasting so much opportunity, especially if you’re looking to add additional work to your machine."

Blake Hamar, President of Cali Raised LED Read customer success story -

"Thanks to our advanced manufacturing techniques, we are able to keep up with demand and keep products in stock where our competition can't."

Blake Hamar, President of Cali Raised LED Read customer success story